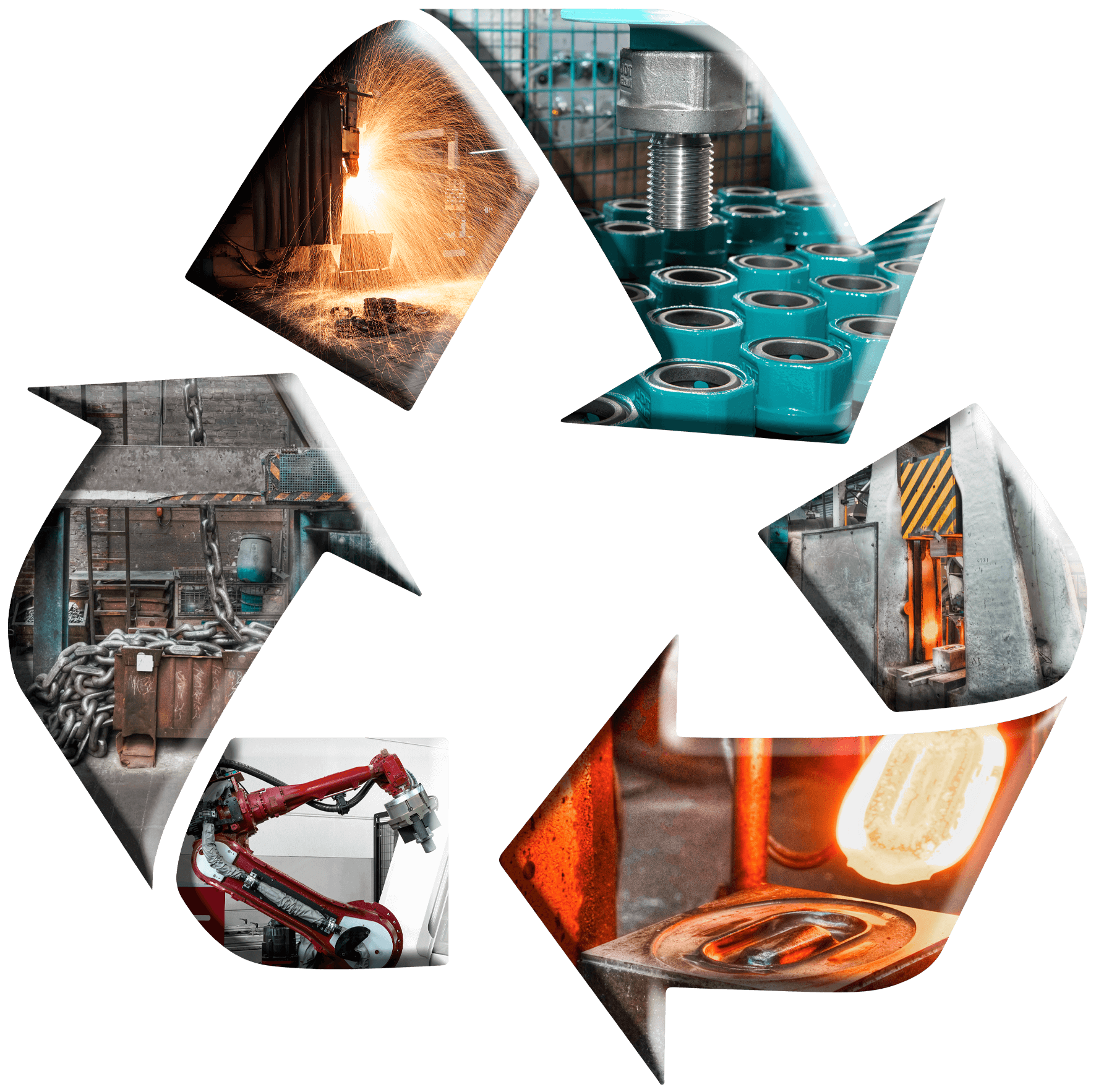

J. D. Theile GmbH & Co. KG (JDT), founded in 1819 at the Schwerte site, is a German steel processing company with a focus on the production of round steel chains and accessories, as well as automation technology. The production range covers the entire process from material crushing, forging process, machining technology, welding technology, heat treatment, surface technology to final testing and dispatch. A high demand on the employees, with the aim of creating high-quality products to the satisfaction of our customers through optimised processes.

Quality

Quality must meet the highest standards with the aim of achieving the greatest possible customer satisfaction. This is why we base our quality standards on the expectations and concepts of our customers. The result is a quality management system that has been consistently practised for years and was certified according to DIN EN ISO 9001 as early as 1994.

Through modern methods and tools of preventive quality assurance, we avoid defects before they occur.

JDT production quality is continuously approved and confirmed both by our customers and external acceptance organisations, among others

- in the industrial product range for chain slings and accessories of quality grade 8, 10 (ENORM) and 12 (MAXNORM) by the worldwide recognised approval of the Employer's Liability Insurance Association (BG)

- for chain slings on offshore containers with DNV approval

DEKRA: JDT was the first manufacturer awarded with the DEKRA δ119 seal for a wide product range.

The use of the seal reflects the conformity of JDT products with high requirements of existing national and international standards. The DEKRA as an internationally recognised testing institute and the associated high testing criteria once again underline JDT's quality awareness and responsibility towards our customers.

The continuous improvement of processes for the creation of products and services, as well as the optimisation of products is a declared goal of the management involving all employees of JDT.

MATERIAL USE

JDT products are generally made of 100% steel and are therefore characterised by a high recycling ability at the end of their life cycle (steel scrap). 100% of the steel scrap can be reused in steel production and thus enters the production and processing cycle repeatedly. A constantly renewing cycle is formed.

Environment

The JDT site is located in the middle of a water protection area, and landscape protection areas are directly adjacent. Awareness and responsibility towards nature and the environment has therefore been a matter of course for the entire staff for many decades. In addition to the legal and official requirements, a certified environmental management system according to DIN EN ISO 14001 is documented and practised.

Energy management

An energy management certified since 2016 and in accordance with ISO 50001 helps to plan and implement energy use and consumption in the company to conserve resources. The goal of energy management is to sustainably optimise energy efficiency in the company and to ensure minimum energy use at a required level of performance. The measures relate to processes, structures, building conditions and systems as well as to human behaviour and its adaptation. Thus, JDT makes its contribution to climate protection and cost reduction.

Waste management

JDT has been practising internal waste management for decades. Avoidance comes before recycling and recycling before disposal.

It goes without saying that recyclable and waste materials are separated according to type and professionally returned to the economic cycle or professionally disposed of in a way that cannot be avoided. Packaging is also largely dispensed with in the marketing of our own products.

Only unavoidable outer packaging for a few individual products or transport packaging is used. The transport packaging is mainly reusable packaging, such as pallet cages, pallets or barrels. JDT wants to contribute at this point already to avoid unnecessary waste in order to protect the environment.

Employees

Our employees make the company and we are aware of this, which is why we treat our staff fairly and in a spirit of partnership. This policy is a requirement for the long-term success of the company. Employee involvement, an open and transparent dialogue with all employees is the prerequisite for the continuous increase in the value of the company. Safety and health protection at work is of highest priority. An internally documented occupational health and safety management system provides the basis for continuous improvement and expansion of occupational safety measures with a future-oriented perspective. Training and briefings keep employees up to date and contribute to safety-conscious thinking and action. Hazards can be minimised by practising risk management and involving authorities and external experts during the planning phase and in the ongoing process. This is a task set by the management with the aim of supporting and sustainably improving occupational health and safety.