INSPECTION OF

LIFTING AND LOAD-HANDLING EQUIPMENT

As a result of improper use or the use of worn, discarded lifting and load-handling equipment, accidents at work unfortunatly tend to occur over and over again in daily operation, in the worst cases even causing personal injury. In order to ensure the safe working condition of lifting and load-handling equipment, it must be inspected by a qualified specialist at regular intervals - at least once a year - in accordance with BetrSichV (German Industrial Safety Standard) and DGUV Standard 100-500 (German Social Accident Insurance Standard), Section 2.8. The inspection intervals should be adapted to the conditions prevailing in operation and the scope of inspection should also be based on the loads in daily use.

As a company backed by more than 200 years of experience, in the field of chain production we have been offering our customers this service for many years, from qualifying their mentation of sling chains, lifting and load-handling equipment, whether with our mobile testing equipment at your site or at our own factory.

OUR ADVISING

YOUR SAFETY

The problems and requirements that you record are transformed into suggested solutions at JDT.

KNOW HOW

SPECIAL LIFTING EQUIPMENT

Why reinvent the wheel, when you can call on similar solutions from our wealth of experience?

SAFETY THROUGH

TRAINING

In our seminars, we present current standards and explain their significance for individual employees in their daily work. Examples are used to illustrate the dangers that arise when dealing with the transport of loads. The one-day seminar focuses on the following topics:

- Introductions to the valid DIN and European Standards (EN)

- Correct handling and selection of sling chains

- Correct selection of lifting equipment

- Correct attachment of loads

- Specifications of a proper chain test

- Documentation of test results

- User information and operating instructions

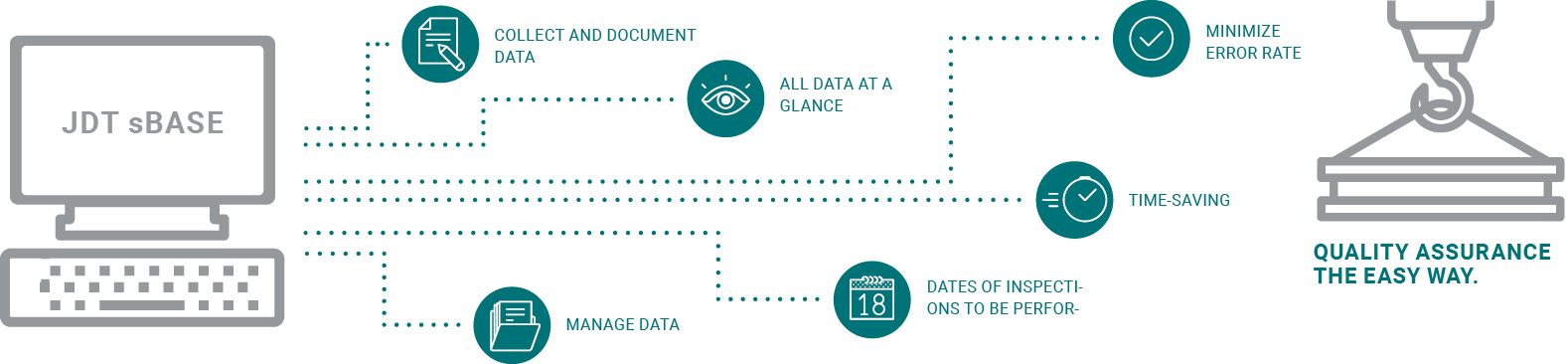

ALL AT A GLANCE

OUR SOFTWARE

Simple recording, management and documentation of work equipment subject to inspection, preconfigured for sling chains

Server-based network version with multiple clients

Management of different clients/branches possible

Import function for already existing electronic tables

Filter function e.g. according to due inspection dates

Print function:

- File Card

- Stop list

- Due test Dates

- Inspection report

Individually configurable:

- Adding item types and components

- Definition o inspection types and inspection intervals

- Creation of parts lists

- Lists of attachments for storing documents e.g. test certificate, declaration of conformity, operating instructions, design drawing, photos, etc.

- Preview image when opening the index card

System requirements:

- Windows 7 operating system, 32 Bit / 64 Bit or higher

- Windows Server 2003 oder higher (with current updates)

- At least 4 GB RAM

- At least 10 GB free hard disk space

DOWNLOAD

BROCHURE

Due to improper use or the use of worn, worn-out lifting and load handling equipment, accidents unfortunately occur time and again in daily operation, in the worst case even with personal injury.

In order to ensure the safe working condition of lifting and load handling equipment, it must be inspected at regular intervals - at least once a year - by a qualified person in accordance with the German Ordinance on Industrial Safety and Health (BetrSichV) and DGUV Rule 100-500, Section 2.8.